close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-09-10 Origin: Site

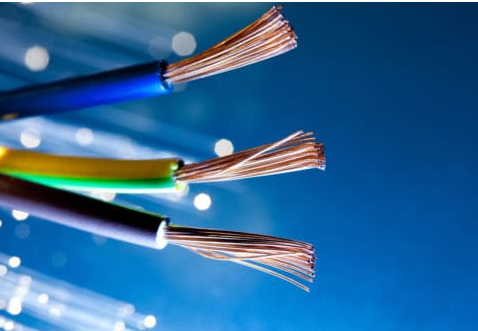

Stranded wire uses many thin copper strands twisted together. This design gives you more flexibility than a single solid wire. You often see stranded wire in devices that move or vibrate.

You can bend and twist it without breaking.

It works well in tight spaces and intricate designs.

If one strand gets damaged, the wire still works.

Choosing the right wire for your project helps you keep your connections safe and reliable.

Stranded wire has many thin copper pieces twisted together. This makes it bend easily and last a long time. It works well when wires must move or bend a lot. You can find it in cars, medical tools, and electronics. Stranded wire keeps working if one piece breaks. This helps your projects stay safe and reliable. Picking the right wire is very important. Stranded wire is best for things that move. Solid wire works better for things that do not move. Always choose stranded wire with good certifications like ISO 9001 and UL. This helps make sure it is safe and works well.

Stranded wire is used in many devices today. It has several thin copper strands twisted together. These strands work together to carry electrical current. This makes the wire more flexible than solid wire. You can bend stranded wire easily. It does not break when you move it a lot.

Stranded wire is best for wiring harness and cable assembly projects that need to bend and last a long time.

Here are the main parts inside a stranded wire cable:

Conductor: Thin copper wires twisted together to carry electricity.

Insulation: A layer made from PVC or XLPE keeps electricity inside.

Shielding: This layer blocks interference from other devices. It is often made from braided copper or aluminum foil.

Filler: This material helps the cable keep its shape.

Bedding: A soft layer protects the inside parts.

Armor: A tough layer guards against damage.

Sheath: The outer cover protects everything inside.

Stranded wire conductors have more strands for extra flexibility. More strands let you bend the wire tighter without breaking it. This design helps the wire last longer in places where you move or bend it a lot.

Stranded wire is made by twisting or braiding many thin wires together. This makes the wire strong and flexible. The way you twist the wires can change how the wire works. Some methods use circles, while others use a bunch or spiral pattern.

Here are the main steps to make stranded wire:

Twist or braid copper wires to make a stranded conductor.

Add insulation to keep electricity inside and protect the wire.

Put on shielding to block outside interference.

Add fillers and bedding to keep the cable stable.

Add armor for extra protection.

Cover everything with a sheath.

This process makes the wire flexible, good at carrying electricity, and able to handle stress. You get a wire that bends easily and lasts longer in tough places.

Feature | Stranded Wire | Solid Wire |

|---|---|---|

Flexibility | Very flexible, bends tightly | Stiff, does not bend much |

Minimum Bend Radius | Can bend in small spaces | Stays straight, bends less |

Fatigue Resistance | Handles lots of bending | Breaks if bent too much |

At Huamao Electronics, we use automatic machines to make stranded wire and wiring harness products. Our workshop has over 25 machines for cutting, peeling, crimping, and wrapping. This technology helps us make high-quality cable assembly solutions quickly and accurately. You get reliable products for cars, phones, and electronics. You can see all our wiring harness and cable assembly products at Huamao Electronics.

Many devices need wires that can move and bend. Stranded wire is special because it bends and twists without snapping. You can use it where wires must move a lot or fit in small spaces. The way stranded wire is made helps stop metal from getting tired and breaking. This keeps your connections strong.

Stranded THHN wire is known for being very flexible. It works well when you need to bend wires a lot or deal with shaking. It does not break or wear out as fast as solid wire.

Stranded wire lasts longer because it fights damage from bending and shaking. This makes it a great pick for places where wires move all the time. You can count on stranded wire to keep your devices working for a long time.

You can bend and twist stranded wire without it breaking.

Stranded wire bends much more than solid wire.

It protects better against metal fatigue than solid core wire.

It handles shaking, weight, and bending very well.

Stranded wire cable is used in many fields. Its bendy and strong design makes it good for jobs where wires must move. Here are some main fields and how they use stranded wire:

Industry | Application Scenarios |

|---|---|

Automotive | Used in control systems and electrical parts for sending signals, running engines, and other car jobs. |

Medical | Used in medical machines like defibrillators and pacemakers. These need to be safe for the body and follow FDA rules. |

Military | Made for tough places, used in military radios and control panels, and meets DoD rules. |

You also see stranded wire in telecom and electronics. It is easy to put in devices that need wires to bend or move a lot.

Stranded wire has many small strands, so it bends easily and is simple to use.

Its design is best for things that bend or move often, like car wiring and portable gadgets.

Stranded wire’s bendiness stops it from breaking when pulled, making it last longer.

It is very useful in places where you need wires to bend and last, like robots and mobile gadgets.

Many strands help electricity flow better, so you lose less power and get good signals.

You can trust stranded wire cable to work well in cars, medical tools, telecom, and electronics. Its bendy and strong build helps keep your gear safe and working right.

When you pick between stranded wire and solid wire, you should think about how they are built and how they work. Stranded wire has lots of thin copper strands twisted together. Solid wire has one thick metal piece in the middle. This makes each wire act differently when you use them.

Here is a table that shows how they are not the same:

Feature | Stranded Wire | Solid Wire |

|---|---|---|

Conductivity | Usually not as good at carrying electricity | Better at carrying electricity |

Flexibility | Bends easily, does not break quickly | Stiff, can snap if bent too much |

Performance | Loses more signal, has more resistance | Stays steady, works better for power |

Construction | Made with many small wires | Made with one big wire |

Current Carrying | Handles less current | Handles more current |

Solid wire lets more electricity flow and can carry more power. Stranded wire bends easier and is better for places that move.

Both wire types have good and bad sides. You should pick the one that fits your project.

Type of Wire | Pros | Cons |

|---|---|---|

Stranded | Bends easily, does not break from small cuts, does not get tired as fast, easy to pull | Costs more, hard to attach to screws, thicker, fills up wire nuts faster |

Solid | Works well in wet spots, easy to attach to screws | Hard to bend, breaks easier if bent a lot |

Tip: If you need wire in a spot that moves or shakes, stranded wire lasts longer. If you need wire that stays still and carries lots of power, solid wire is better.

Solid wire is simple to attach and works well in dry, still places. Stranded wire is easy to fit in tight spots and bends without snapping.

Pick stranded wire if you need wire that bends. It is best for places where wires move, bend, or shake. You see stranded wire in robots, cars, and portable gadgets. It is also easy to pull through pipes with lots of turns.

Here are times when stranded wire is the best pick:

You need wire in a moving part or a spot that shakes.

You want wire to go around corners or fit in small spaces.

You need wire that will not snap after bending many times.

Solid wire works best in these cases:

You need wire for a dry, still place.

You want wire that is easy to attach to screws or plugs.

You need wire that carries more power and has less resistance.

Note: Stranded wire is great for places that move or shake a lot. Solid wire is better for spots where the wire stays still.

When you put in wire, you will see some differences:

Stranded wire is tough and bends well, good for places that move or shake.

Solid wire keeps its shape but can snap if bent too much.

Stranded wire is easy to bend and fit in small spaces.

Solid wire is stiff and best for places where you do not need to bend it.

Both wire types can fail in some ways, like the conductor breaking, the insulation cracking, the shield breaking down, or the jacket getting damaged. You can stop these problems by picking the right wire for your job.

If you want your wires to last, always pick the right type for your project. Stranded wire gives you bendiness and strength in moving parts. Solid wire gives you power and dependability in places that do not move.

You want your stranded wire cable to work well every time. At Huamao Electronics, we use advanced machines to make this happen. Our machines do everything from cutting and peeling to crimping and testing. They use special motors to cut wires to the right length. The machines peel and crimp wires with exact molds. This makes sure every wire looks like the design.

Automation gives you many good things:

Wire lengths, ends, and connections are always the same.

Cutting and stripping wires exactly helps them work well.

Production is faster and there are fewer mistakes.

Here is a table that shows how automation and manual work compare:

Aspect | Automation | Manual Processes |

|---|---|---|

Consistency | Wire lengths and ends are always the same | Consistency changes |

Defect Rates | Fewer mistakes and problems | More mistakes and problems |

Automation also helps save money. You pay less for workers and waste less material. Companies using wire stranding machines can make up to 50% more wires.

You want every stranded wire to be safe and meet rules. Huamao Electronics checks everything carefully. We look at materials before making wires. We watch every step and test wire size and strength during production. After making wires, we check them again to make sure they are safe and work well.

Here are some important ways we check quality:

Check materials before making wires

Watch the production process

Test wires during production

Check wires after making them

Certifications are important for safety and quality. Huamao Electronics has ISO 9001, UL, CE, and IPC/WHMA-A-620 certifications. These rules help make sure your wire harnesses are safe and work well. IPC/WHMA-A-620 tells us how to make good cable and harness assemblies. UL and CE show our wires are safe for important places. ISO 9001 helps us keep getting better.

Certification | Impact on Quality |

|---|---|

ISO 9001 | Makes sure we check quality and keep improving. |

UL Certification | Shows our products are safe for important places. |

IPC/WHMA-A-620 | Gives rules for good quality, safety, and reliability. |

CE | Shows our products meet European safety and environment rules. |

You can trust Huamao Electronics to give you stranded wire cable that meets high standards. Our machines and careful checks help you get reliable products every time.

Stranded wire is flexible and strong. It works well in many cables. You can see its good points in this table:

Benefit | Description |

|---|---|

Flexibility | Bends easily and does not break |

Cost-effectiveness | Saves money by making wires quickly |

Fatigue resistance | Handles shaking and moving without problems |

High-frequency use | Good for fast signals |

Versatility | Can be used inside or outside |

Pick stranded wire from certified suppliers with modern machines. This gives you products you can trust and keeps customers happy. Always choose wire that fits your project for the best results.

Stranded wire uses many thin strands twisted together. Solid wire uses one thick piece of metal. You get more flexibility with stranded wire. Solid wire gives you more strength for still places.

You should use stranded wire in places that move or bend often. It works well in cars, robots, and portable devices. You can also use it in tight spaces where you need to pull wire around corners.

Stranded wire bends without breaking. The many strands share the stress. You get less metal fatigue. This helps your wire harness or cable assembly last longer in machines that move.

You should check for certifications like ISO 9001, UL, and IPC/WHMA-A-620. High-quality stranded wire feels smooth and bends easily. Huamao Electronics tests every wire to make sure you get safe and reliable products.

You can use stranded wire for many jobs, but solid wire often carries more power. Stranded wire works best for flexible connections. Always check your project’s needs before you choose the wire type.