close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-09-22 Origin: Site

In the world of electrical installations, the choice of cable is paramount to ensuring safety, efficiency, and longevity of the electrical system. Among the various types of cables available, metal clad cable has emerged as a preferred option for its unique combination of strength and flexibility. This article delves into the intricacies of metal clad cable, exploring its features, applications, and the advantages it offers over traditional wiring methods.

Metal clad cable is a strong and flexible wiring solution widely used in residential, commercial, and industrial settings. It contains insulated conductors surrounded by a protective metal sheath. This sheath can be smooth, ridged, or interlocking, providing durability while allowing flexibility.

Metal clad cable often includes a full-size ground wire. Some versions have a PVC jacket for wet locations or direct burial. It protects wires from abrasion, fire, water, and environmental hazards, making it a preferred choice for electricians handling electronic cables and other electrical systems.

Metal clad cable comes in several types, each suitable for specific environments and applications:

| Type | Material | Key Features | Typical Uses |

|---|---|---|---|

| Aluminum Interlocked Armor | Aluminum | Flexible, flame-retardant, water-resistant | Industrial plants, pulp & paper, mining |

| Continuously Corrugated Copper Weld | Copper, aluminum, bronze, steel | Water-resistant, medium voltage | Instrumentation, controls, petrochemical |

| Steel Wire Armor | Galvanized steel | Strong, abrasion-resistant | Underground power lines, heavy machinery |

| Galvanized Armor | Steel + PVC | Corrosion-resistant, direct burial | Mining, wet or oily industrial sites |

Choosing the correct type depends on voltage, environment, and whether the installation is indoor, outdoor, or direct burial.

In homes, metal clad cable is versatile and can be used in multiple wiring situations:

Service circuits: Connecting the main electrical panel to the utility supply.

Branch circuits: Wiring outlets, lights, and small appliances throughout the house.

Feeder circuits: Connecting subpanels or secondary panels.

Garages and basements: PVC-jacketed cables allow safe use in wet areas.

Concealed wiring: Runs behind walls or in tight spaces where flexibility is required.

Because metal clad cable does not always require conduit, it simplifies installations, reduces labor, and saves materials while ensuring safety.

Metal clad cable is widely used in commercial buildings due to its durability and versatility:

Offices and high-rise buildings: Safe for high-traffic areas, wet locations, and long cable runs.

Hospitals and healthcare facilities: Provides protection against water, cleaning chemicals, and environmental hazards.

Retail and entertainment facilities: Can handle high electrical loads while being flexible for complex layouts.

Large infrastructure projects: Cable flexibility allows it to be installed around corners, between floors, and across ceilings.

Specialized areas: Control rooms, lighting panels, and HVAC systems benefit from the durability and protection of metal clad cable.

Its ability to resist impact, moisture, and fire makes it a preferred option for most commercial wiring projects.

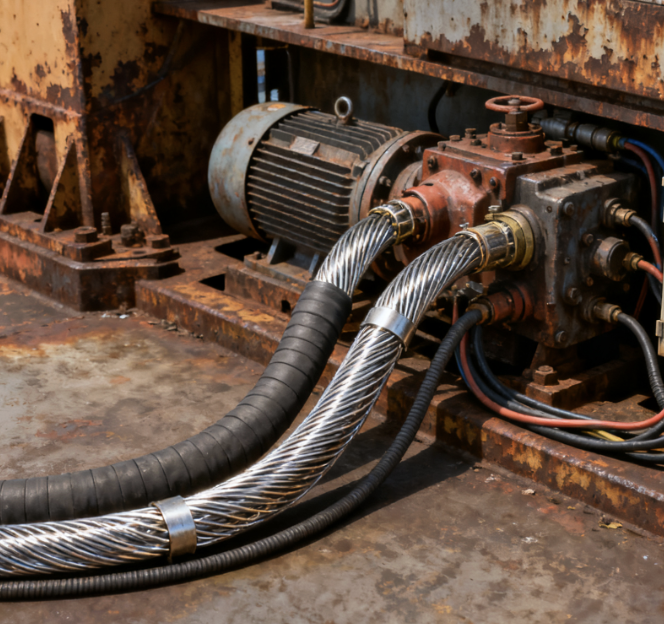

Industrial sites demand extra protection, and metal clad cable is ideal for these environments:

Factories and assembly plants: Resists vibration, abrasion, and exposure to chemicals.

Petrochemical plants: Can withstand hazardous locations and corrosive environments.

Mining operations: PVC jackets and armored sheaths protect against water, dust, and mechanical damage.

Heavy machinery: Delivers power to motors, control panels, and equipment while maintaining safety.

High-voltage and medium-voltage applications: Certain types of metal clad cable, like Continuously Corrugated Copper Weld or Steel Wire Armor, handle these loads efficiently.

In industrial environments, metal clad cable often runs alongside electronic cables for control systems, automation, and instrumentation. Proper separation ensures no interference occurs between power and low-voltage signals.

Metal clad cable can be used outdoors and in wet locations when appropriately rated:

Direct burial: PVC-jacketed cables survive underground installation without conduit.

Wet or oily conditions: Galvanized armor or PVC-jacketed cables resist corrosion.

Industrial yards and utility sites: Protects against environmental damage while powering lights, motors, and equipment.

Public infrastructure: Safe for street lighting, pumps, and electrical panels in municipal applications.

These cables allow electricians to run wiring in challenging environments without extensive conduit work, saving time and labor.

Electricians choose metal clad cable for several reasons:

One of the primary advantages of metal clad cable is its flexibility. Unlike rigid conduit, metal clad cable can easily bend around corners, ceilings, and tight spaces without damaging the conductors inside. This flexibility simplifies installation processes and allows for easier routing through complex architectural designs. It also helps in navigating areas that would be challenging for rigid conduit systems, making it an ideal choice for intricate installations.

The durability of metal clad cable is another significant benefit. The interlocked steel or aluminum armor not only protects the wires from mechanical damage but also from environmental factors such as fire, impact, moisture, and abrasion. This robust protection ensures the longevity of the cable and enhances the safety of electrical systems, making it suitable for a wide range of applications, including those that demand high resistance to external threats.

The conduit-free installation of metal clad cable is a major advantage in terms of cost and efficiency. By eliminating the need for a separate conduit, material costs are reduced, and the installation process is streamlined. This not only saves on materials but also on labor, as fewer components need to be handled and installed. The result is a more cost-effective solution that is quicker to deploy, reducing overall project timelines.

The versatility of metal clad cable makes it suitable for a variety of settings, including residential, commercial, industrial, and outdoor installations. Its ability to adapt to different environments and applications makes it a popular choice among electricians and engineers. Whether used in a home renovation, a commercial building, an industrial facility, or an outdoor project, metal clad cable provides reliable performance and protection.

The cost-effectiveness of metal clad cable is evident in its faster installations, which translate to fewer labor hours and a cleaner, more organized layout. The ease of installation, combined with the durability and protection offered by the cable, results in a more economical solution compared to traditional wiring methods that require additional conduit systems. This cost savings can be significant, especially in larger projects where the use of metal clad cable can reduce both material and labor costs.

Metal clad cable’s compatibility with electronic cables in mixed installations is another advantage. It can be used alongside other types of cables without compromising the integrity of the electrical system. This makes it a versatile choice for modern installations where a combination of power and signal cables is often required. The ability to integrate seamlessly with electronic cables ensures that metal clad cable can meet the demands of contemporary electrical systems.

Yes, if it is PVC-jacketed or rated for direct burial.

Most have 2–4 conductors, but UL does not set a strict limit.

Yes, for many indoor applications. Metal boxes are required.

PVC-jacketed Galvanized Armor or Teck90 cables.

Yes, proper separation avoids interference, allowing power and low-voltage control systems to coexist safely.

Metal clad cable is a flexible, durable, and versatile solution for residential, commercial, industrial, and outdoor electrical installations. It simplifies installation, protects conductors, and reduces labor costs. Its ability to work alongside electronic cables makes it a reliable choice for almost any project.

For those seeking high-quality metal clad cables, Huamao Cable stands out as a leading manufacturer and supplier. With a commitment to innovation and quality, Huamao Cable offers a comprehensive range of metal clad cables designed to meet the rigorous demands of various applications. Their products are known for their superior protection against mechanical damage and environmental factors, ensuring long-lasting performance and safety.