close

Choose Your Site

Global

Social Media

In modern electronic and industrial manufacturing, seamless connectivity is essential for ensuring system performance, safety, and reliability. From advanced communication networks to automotive electronics, virtually every piece of equipment relies on high-quality cable assemblies to transmit power and data. At the heart of producing these critical components is a specialized role: the cable assembler.

A cable assembler is a skilled technician responsible for constructing, testing, and maintaining cable assemblies — the complete electrical interconnection systems that include wires, connectors, terminals, and protective housings. While cable assemblies may appear straightforward, they are complex components that demand precision, technical expertise, and a deep understanding of electrical and mechanical principles. Cable assemblers ensure that these components meet strict industry standards and function reliably across a wide range of applications.

A cable assembler is a professional who specializes in the fabrication and assembly of electrical and data cables. Their primary objective is to create functional cable assemblies that meet precise specifications, ensuring both electrical performance and mechanical durability.

Cable assemblers typically work in manufacturing facilities, electronic assembly plants, or industrial production lines. Their environments often include specialized workstations equipped with tools for wire cutting, stripping, crimping, soldering, and connector installation. Depending on the industry, cable assemblers may also operate in clean rooms for sensitive electronics or in high-volume production settings where efficiency is critical.

In some companies, cable assemblers are also involved in custom cable assembly production, working closely with engineers and designers to produce specialized solutions for unique applications. These may include automotive wiring harnesses, industrial automation cables, medical device connectors, and telecommunications equipment.

To succeed as a cable assembler, a combination of technical knowledge, precision, and problem-solving skills is essential. Key competencies include:

Electrical knowledge: Understanding voltage, current, signal transmission, and insulation requirements.

Manual dexterity: Handling small wires and connectors accurately.

Reading schematics and diagrams: Translating technical drawings into accurate cable assemblies.

Attention to detail: Ensuring proper alignment, correct connector installation, and compliance with specifications.

Problem-solving: Identifying and troubleshooting defects in wires, connectors, or finished assemblies.

A cable assembler’s role is highly technical, requiring both practical skills and a foundational understanding of electrical systems.

The work of a cable assembler is multi-faceted, spanning the entire lifecycle of a cable assembly from raw materials to the final tested product. The key responsibilities include:

One of the primary tasks is combining individual wires, cables, and connectors into a complete cable assembly. This process may involve:

Stripping insulation from wires to expose conductors

Inserting wires into connectors or terminals

Crimping, soldering, or overmolding connectors for secure attachment

Bundling multiple cables together according to specifications

Precision is critical to ensure that each assembly meets design requirements and maintains electrical integrity.

Cable assemblers perform rigorous testing to verify that assemblies function correctly. This may include:

Continuity testing: Ensuring all connections are electrically sound

Signal testing: Checking data transmission quality for high-speed or LVDS cables

Resistance and insulation testing: Confirming durability and safety

Visual inspections: Identifying potential defects such as bent pins, poor crimps, or frayed wires

Quality assurance is a vital part of the role, as faulty cable assemblies can lead to system failures, safety risks, or costly downtime.

Cable assemblers rely heavily on technical schematics and wiring diagrams to construct assemblies accurately. These documents specify wire types, lengths, color codes, connector types, and assembly sequences. An assembler must interpret these plans with precision to prevent errors and ensure that the final product functions as intended.

Installation of connectors and terminals is a key responsibility. Depending on the type of cable assembly, this may involve:

IDC (Insulation Displacement Connectors): Piercing wire insulation for secure contact

Molded connectors: Overmolding connectors to prevent moisture ingress and mechanical stress

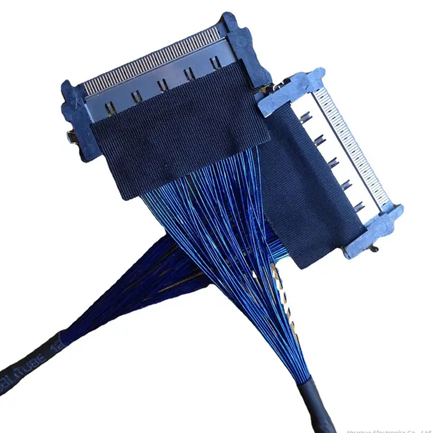

LVDS connectors: High-speed signal connectors requiring careful alignment and handling

Correct installation ensures optimal electrical performance and mechanical stability.

Cable assemblers often identify and resolve issues during assembly or testing. Troubleshooting may involve:

Locating short circuits or open connections

Adjusting misaligned connectors

Replacing defective wires or terminals

Ensuring compliance with environmental and mechanical standards

This problem-solving aspect ensures that only high-quality assemblies reach customers.

Cable assemblers work with a variety of assembly types, each designed for specific applications:

Molded assemblies feature connectors permanently encased in thermoplastic or elastomer materials. The overmolded design protects against moisture, vibration, and mechanical stress, making them ideal for automotive, industrial, and medical applications.

IDC (Insulation Displacement Connector) assemblies are designed for high-density wiring. They allow fast, secure connections without stripping insulation, making them common in telecommunications, data centers, and industrial equipment.

Low-Voltage Differential Signaling (LVDS) assemblies support high-speed data transmission with minimal power consumption. They are used in LCD displays, automotive infotainment systems, machine vision, and industrial cameras.

Custom assemblies are tailored to meet specific client requirements, including unique connector types, cable lengths, shielding, or environmental resistance. These are critical in military, medical, and industrial applications, where standard assemblies may not suffice.

A skilled cable assembler relies on a combination of technical knowledge, hands-on experience, and specialized tools to produce high-quality and reliable cable assemblies. This role requires proficiency across multiple domains, including technical skills, the use of specific tools and machines, and essential soft skills. Each aspect contributes to the assembler’s ability to deliver assemblies that meet strict industry standards and perform effectively in their intended applications.

Technical expertise forms the foundation of a cable assembler’s work. Key skills include:

Electrical and Mechanical Knowledge: Understanding the flow of current, voltage ratings, insulation properties, and mechanical durability requirements is crucial for building reliable cable assemblies.

Ability to Read and Interpret Wiring Diagrams: Assemblers must translate complex schematics and technical drawings into physical assemblies, ensuring correct wire routing, connector placement, and proper electrical connectivity.

Understanding of Industry Standards: Knowledge of standards such as ISO, RoHS, and IPC ensures that assemblies comply with safety, quality, and environmental regulations.

Troubleshooting and Quality Assurance Techniques: Identifying and resolving potential faults during assembly prevents signal loss, short circuits, or other failures, guaranteeing that each assembly functions correctly under demanding conditions.

Cable assemblers use a range of tools and equipment to perform precise assembly tasks:

Wire Strippers and Cutters: For preparing wires with accuracy and efficiency.

Crimping Tools and Soldering Equipment: Ensures secure connections between wires and terminals.

Heat Shrink and Overmolding Tools: Provides insulation, mechanical protection, and resistance to environmental stress.

Electrical Testers and Multimeters: Essential for verifying continuity, signal integrity, and resistance, ensuring every cable assembly meets performance standards.

Soft skills are equally important for success in cable assembly work:

High Attention to Detail: Ensures every wire, connector, and terminal is installed correctly, avoiding errors that could compromise functionality.

Manual Dexterity and Steady Hand Coordination: Allows for careful handling of delicate components, particularly in high-density or small-scale assemblies.

Problem-Solving Mindset: Enables assemblers to quickly identify, diagnose, and resolve assembly issues.

Effective Communication and Teamwork: Critical for collaborating with other assemblers, engineers, and quality control staff to maintain production efficiency and consistency.

By combining these technical skills, specialized tools, and soft skills, cable assemblers ensure that each cable assembly is durable, reliable, and capable of performing flawlessly in a variety of applications, from automotive and industrial systems to consumer electronics and telecommunications.

Cable assemblers are essential across many sectors, including:

Cable assemblies power engine control units, infotainment systems, safety sensors, and battery management systems. Assemblers ensure durability against temperature fluctuations, vibrations, and chemical exposure. In electric vehicles, high-precision assemblies are critical for safety and performance.

Factories and automated facilities rely on cable assemblies to connect sensors, actuators, control panels, and robots. Assemblers ensure reliability in environments subject to mechanical stress, oil, and EMI (electromagnetic interference).

Assemblers produce cable assemblies for televisions, gaming consoles, audio systems, and home appliances, ensuring user-friendly functionality and durability.

IDC and LVDS cable assemblies created by skilled assemblers enable high-speed data transmission between routers, switches, and networking devices, maintaining stable communication for data centers and communication networks.

Cable assemblers are more than assembly line workers; they are highly skilled professionals who ensure the reliability, safety, and performance of critical electrical systems. From assembling wires and connectors to testing high-speed signal assemblies, their expertise directly impacts the quality of cable assemblies across industries.

High-quality cable assemblers are essential for producing molded, IDC, LVDS, and custom cable assemblies, meeting strict performance standards and supporting complex systems. Their work reduces equipment failures, ensures signal integrity, and enhances operational efficiency.

For manufacturers and OEMs seeking dependable interconnection solutions, partnering with a professional team of cable assemblers is key.

Huamao Cable offers expertise in a wide range of cable assemblies, leveraging skilled cable assemblers to deliver precision-engineered, reliable, and customized solutions.

Contact Huamao Cable today for expert cable assembly services and customized interconnection solutions — connecting your technology to performance and reliability.

1. What does a cable assembler do?

A cable assembler builds, tests, and maintains cable assemblies, ensuring reliable electrical performance and mechanical durability.

2. What types of cable assemblies do they work with?

They work with molded, IDC, LVDS, and custom cable assemblies for automotive, industrial, consumer electronics, and telecom applications.

3. What skills are essential for a cable assembler?

Electrical knowledge, reading schematics, troubleshooting, attention to detail, manual dexterity, and teamwork, plus familiarity with standards like ISO, RoHS, and IPC.

4. What tools do cable assemblers use?

Wire strippers, crimping and soldering tools, heat shrink and overmolding equipment, and electrical testers/multimeters.