close

Choose Your Site

Global

Social Media

In today’s increasingly connected world, electrical and data transmission systems form the foundation of almost every modern device and industrial process. From automotive electronics to advanced communication networks, seamless power and signal flow are essential to keep operations running efficiently. At the heart of these systems lies an often overlooked but critical component — the cable assembly.

A cable assembly refers to a group of electrical cables or wires that are bundled together and terminated with connectors to transmit power, data, or signals. While these assemblies may appear simple at first glance, they play a crucial role in ensuring that equipment performs reliably under a variety of operating conditions — including exposure to heat, vibration, moisture, or electromagnetic interference.

Many people often ask, “How is a cable assembly different from a wire harness?” Though the two terms are sometimes used interchangeably, they serve distinct purposes. A wire harness typically organizes individual wires for routing electricity in relatively protected environments, while a cable assembly is built to provide added protection, shielding, and mechanical strength — ideal for demanding applications where performance and durability are key.

A cable assembly is an engineered electrical component composed of multiple insulated wires, cables, connectors, terminals, and protective coverings that are assembled together to form a complete interconnection solution. These assemblies are designed to transmit both electrical power and data signals between devices or components.

In simpler terms, cable assemblies act as the “nervous system” of any electronic or mechanical system, ensuring smooth communication and uninterrupted energy flow. They are commonly manufactured using materials such as copper conductors, thermoplastic insulation, and robust outer jackets to withstand mechanical stress and environmental challenges.

Cable assemblies serve several vital functions in modern equipment:

Signal Transmission: They ensure accurate and stable transmission of electrical signals or data between components.

Power Distribution: Cable assemblies safely distribute electrical power from the source to various parts of a system.

Mechanical Protection: The outer sheaths, shields, and molded housings provide excellent resistance to abrasion, vibration, and external contaminants.

While both are essential interconnection systems, their design intent differs:

Wire Harness: Usually a collection of individual wires bundled with simple insulation or sleeving, mainly used in protected environments inside machinery or vehicles.

Cable Assembly: Enclosed within a durable protective layer or molded housing, suitable for outdoor, industrial, or high-stress conditions.

Therefore, when equipment demands resilience, water resistance, or electromagnetic shielding, the cable assembly is the superior choice. For customers requiring tailored configurations, a custom cable assembly can be engineered to meet specific mechanical and electrical specifications.

Cable assemblies are not one-size-fits-all products. Depending on the operating environment, performance requirements, and application, they come in various configurations. Below are some of the most common and high-performance types:

Molded cable assemblies feature connectors that are permanently molded onto the cables using thermoplastic or elastomer materials. This overmolding process provides exceptional protection against moisture, vibration, and strain, ensuring a long service life even in harsh conditions.

These assemblies are widely used in automotive electronics, industrial equipment, and medical devices, where exposure to dust, oil, or mechanical stress is common. The molded construction prevents connectors from loosening or corroding, resulting in reliable electrical connections over time. Additionally, the smooth molded finish allows for easy handling and compact installation in tight spaces.

Insulation Displacement Connector (IDC) cable assemblies are designed for precise and high-density connections, particularly in data and communication systems. Instead of requiring stripped wire ends, IDC connectors pierce the wire insulation to make secure electrical contact, ensuring consistent signal quality and reducing assembly time.

Huamao’s IDC cable assemblies utilize precision-engineered contacts that minimize signal loss, crosstalk, and interference. This makes them ideal for data centers, networking equipment, industrial automation systems, and telecommunication devices where accuracy and speed are paramount.

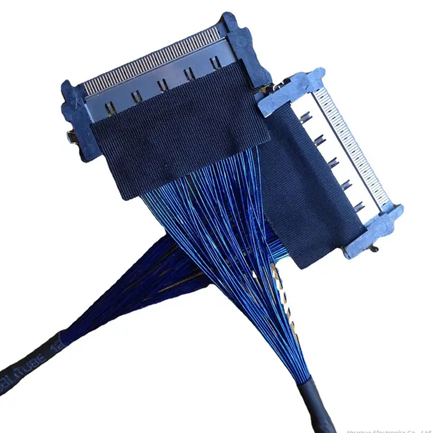

Low-Voltage Differential Signaling (LVDS) cable assemblies are designed for high-speed data transmission while consuming minimal power. LVDS technology, standardized as TIA/EIA-644, supports rapid serial communication using inexpensive twisted-pair copper cables.

LVDS cable assemblies are widely used in LCD displays, automotive infotainment systems, industrial cameras, and machine vision systems. They are particularly valued for their ability to maintain signal integrity over long distances and at high frequencies — essential for transmitting video, graphics, and real-time sensor data.

Every industry has unique requirements, and off-the-shelf solutions do not always suffice. That’s where custom cable assemblies come in. Huamao Cable specializes in designing and manufacturing tailor-made assemblies to meet the exact specifications of clients.

Whether it’s specific connector types, wire gauges, shielding requirements, or environmental resistance, custom cable assemblies ensure compatibility and reliability for specialized applications. Typical examples include medical equipment, military-grade electronics, renewable energy systems, and automotive control units.

Cable assemblies are integral to virtually every modern industry. Their versatility and adaptability make them indispensable for a wide range of applications, from consumer electronics to mission-critical industrial systems.

In today’s vehicles, cable assemblies power everything from engine control units (ECUs) and infotainment systems to safety sensors and battery management modules. These assemblies are engineered to endure temperature fluctuations, vibrations, and exposure to chemicals, ensuring reliable vehicle performance and safety.

Custom automotive cable assemblies also play a crucial role in electric vehicles (EVs), where efficient power management and precise signal communication are essential for performance optimization.

In factories and automated facilities, industrial cable assemblies connect sensors, actuators, control panels, and robotic systems. These assemblies are designed for rugged environments, providing high flexibility, oil resistance, and EMI (electromagnetic interference) shielding.

Reliable industrial cable assemblies help prevent downtime, maintain production efficiency, and ensure safe operations in environments where precision and durability are non-negotiable.

From televisions and gaming consoles to audio systems and home appliances, cable assemblies deliver the connectivity that enables user-friendly and efficient device operation. Molded cable assemblies, in particular, are popular in consumer electronics due to their sleek design, cost-effectiveness, and reliability.

In the world of digital communication, cable assemblies ensure seamless data transfer between routers, modems, switches, and network infrastructure. The precision of IDC and LVDS cable assemblies enables high-speed communication with minimal signal degradation, making them critical for maintaining stable connectivity in modern networks and data centers.

Investing in high-quality cable assemblies offers significant advantages beyond simple connectivity. Whether for industrial automation or consumer products, quality design and manufacturing ensure long-term performance and cost efficiency.

Premium cable assemblies are engineered to deliver stable and consistent electrical performance. Precision manufacturing eliminates weak connections and minimizes signal loss, interference, and noise. This reliability is essential for mission-critical systems where downtime or communication errors can be costly.

High-quality assemblies are built to withstand extreme temperatures, vibration, and physical stress. Features like strain reliefs, overmolding, and braided shielding ensure mechanical robustness and extended lifespan.

Cable assemblies often include water-resistant and dust-proof designs (IP-rated), protecting internal conductors from corrosion and oxidation. Such features make them ideal for outdoor or industrial environments where exposure to moisture, oil, or debris is unavoidable.

Reliable connections minimize the risk of system failures, reducing the need for frequent repairs or replacements. This translates to improved operational uptime and reduced total cost of ownership.

Every system is unique, and the ability to design a custom cable assembly ensures perfect compatibility with the intended application. From connector selection and cable length to shielding and labeling, customized solutions optimize performance while meeting specific industry standards and regulatory requirements.

In summary, a cable assembly is far more than a collection of wires — it is a sophisticated, purpose-built interconnection system that enables the reliable operation of countless electronic, automotive, industrial, and communication devices. By combining electrical performance, mechanical protection, and design flexibility, cable assemblies ensure that complex systems work efficiently and safely under all conditions.

As industries evolve toward higher automation, faster data transfer, and greater environmental resilience, the demand for custom cable assemblies continues to grow. Manufacturers and OEMs require trusted partners capable of delivering precision-engineered, durable, and compliant interconnection solutions.

Huamao Cable stands at the forefront of this field, offering expertise in molded, IDC, LVDS, and custom cable assemblies for a broad range of industries. With advanced manufacturing capabilities, rigorous quality control, and commitment to innovation, Huamao Cable ensures that every product meets the highest performance and reliability standards.

Contact Huamao Cable today for reliable and customized cable assembly solutions — designed to connect your technology to the future.

A cable assembly includes multiple wires, connectors, and protective coverings designed for durability, shielding, and high-performance applications, while a wire harness mainly organizes wires for basic routing in protected environments.

Common types include molded cable assemblies for durability, IDC cable assemblies for high-density connections, LVDS cable assemblies for high-speed data transfer, and custom cable assemblies tailored to specific industry needs.

Cable assemblies are used across multiple industries, including automotive systems, industrial automation, consumer electronics, and telecommunications, ensuring reliable power and signal transmission.

Custom cable assemblies are designed to meet unique specifications, offering precise connector types, shielding, lengths, and environmental resistance to ensure optimal performance for specialized applications.