close

Choose Your Site

Global

Social Media

You use wire connectors by putting bare wires together. Then you hold them tight with the right connector for your job. Always think about safety first. Pick the right size and kind, like a terminal connector or wiring harness, that fits your wires. If you have not done this before, do not worry. You can use wire connectors safely with a few easy steps.

Tip: Check your connections two times before turning anything on for the best results.

Pick the right wire connector for your wire size and job. This helps keep your connections safe and strong. Prepare wires by stripping off the right amount of insulation. Make sure the wire ends are clean. This gives you a good connection. Use the right tools like wire strippers and crimping tools. Wear safety gear to protect yourself and make work easier. Follow the steps for each connector type. These include twist-on, push-in, lever, or screw terminal connectors. This helps make sure your connections are secure. Always check your work when you finish. Turn off the power before you start. Call a professional if you see any electrical problems.

Picking the right wire connectors is very important. It helps keep your electrical work safe and strong. You want your wires to stay in place and last a long time. Huamao Electronics has many connector choices. You can always find one that fits your project.

There are a few main types of wire connectors you can buy. Each one works best for certain jobs. Here is a quick look at the most common types:

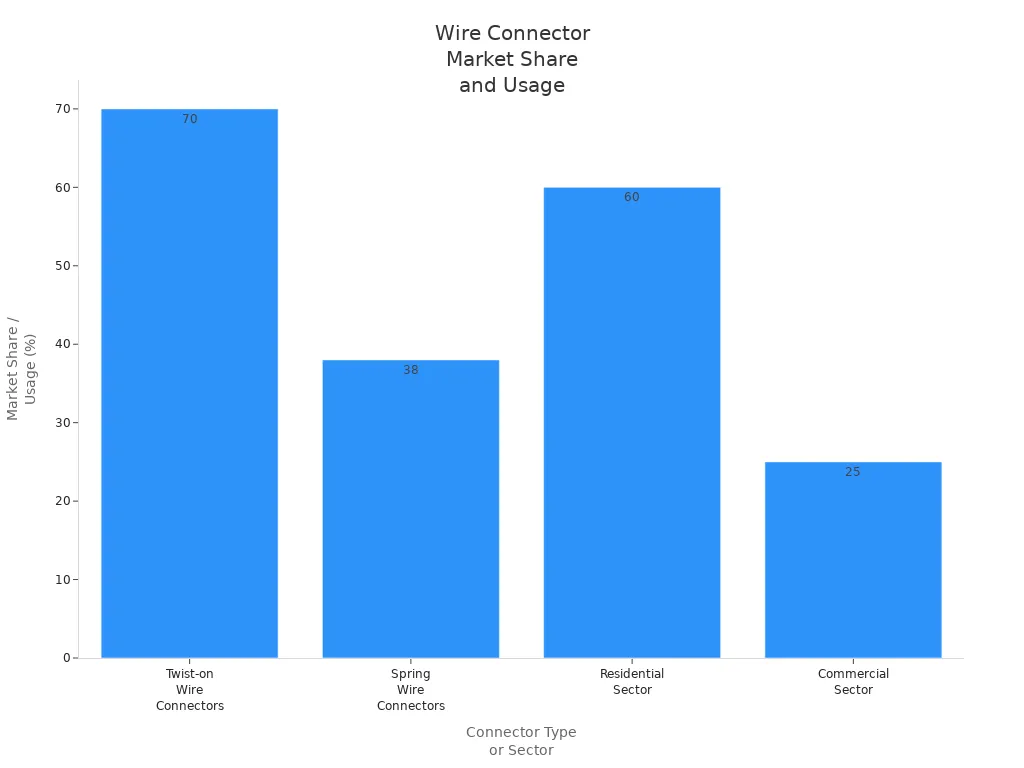

Wire Connector Type | Usage Context | Market Share / Sales Data | Regional Insights | Leading Companies & Market Share Details |

|---|---|---|---|---|

Twist-on Wire Connectors | Used in homes, lights, and machines | Over 3.2 billion sold in 2023; 70% of U.S. electricians use them | North America: over 40% of all connectors; U.S. sold 1.2 billion in 2023 | Huamao Electronics, 3M makes 600 million each year |

Spring Wire Connectors | Good for places with shaking or lots of repairs | Used in 38% of switchboards; 45% used in East Asia factories | Asia-Pacific: 28% more used in South Korea each year | Huamao Electronics, WAGO is a leader |

Application Sector | Residential | About 60% of all connectors are used in homes | Many new homes built in North America and Europe (over 9 million in 2023) | - |

Application Sector | Commercial | About 25% of all connectors are used in businesses | More smart lights and control panels; over 2,000 smart buildings wired in Japan in 2023 | - |

Application Sector | Industrial | Needs connectors that last a long time | Used in mining, oil, car factories; spring connectors are best for shaking | - |

You will see twist-on connectors, or wire nuts, in most houses. Spring connectors are good for places that shake, like factories. Lever, push-in, screw terminal, and crimp-on connectors are also used for different jobs.

Tip: Always check what kind of connector you need before you start. The right one makes your work safer and easier.

You must match your connector to your wire for safety. Here is what you should check:

Make sure the wire gauge fits the connector size. For example, ring terminals fit 10-22 AWG wires.

Look at the insulation type and thickness. Some connectors have nylon, vinyl, or heat shrink covers for extra safety.

Use color codes to help you pick the right size. Red is for 22-18 AWG, blue for 16-14 AWG, and yellow for 12-10 AWG.

Pick the connector type that fits your job. You can choose from ring, spade, butt splice, disconnects, snap plugs, piggyback disconnects, tap splices, and closed end connectors.

Make sure the connector fits your wire and the terminal size is right.

Check the voltage and current ratings. Always use connectors that match your wire’s needs.

Think about where you will use the wires. If they are outside or in wet places, use waterproof or rust-proof connectors.

Choose brands you trust, like Huamao Electronics, for good quality and safety.

If you want to know more about connectors, visit the Huamao Electronics product page for wiring harnesses, terminal connectors, and more.

Before you start working with wire connectors, you need the right tools and safety gear. Getting prepared makes your job easier and keeps you safe. Let’s look at what you need.

You want your connections to be strong and reliable. Here’s a list of tools you should have on hand:

Wire strippers and cutters – Use these to remove insulation and cut wires cleanly. This step helps you get a neat end for your terminal connector or wiring harness.

Crimping tool – This tool presses the connector onto the wire, making sure it stays tight and secure. A good crimp means your connection will last.

Heat shrink tubing and heat gun – Slide heat shrink tubing over your connection, then use the heat gun to seal it. This protects your electronic wire from moisture and corrosion.

Multimeter – Always test your finished connection. A multimeter checks if electricity flows the right way, so you know your work is safe.

Tip: Set up your workspace before you begin. Gather all your tools and keep them within reach. This saves time and helps you avoid mistakes.

If you want a complete kit, Huamao Electronics offers connector tool sets that include everything you need for cable assembly and more. These kits work well for both beginners and pros.

Safety comes first when working with electricity. You should always wear the right gear to protect yourself:

Hard hat – Shields your head from bumps and electric shock.

Safety glasses or face shield – Protects your eyes from sparks or flying bits.

Insulated gloves – Keeps your hands safe from electric shock.

Safety shoes – Non-conductive soles help prevent shocks through your feet.

Flame-resistant clothing – Guards your body from heat or fire in case of an accident.

Ear protection – Use earplugs or earmuffs if you work in a noisy area.

Note: These safety tips follow standards from trusted groups like the NFPA and ANSI. Never skip safety gear, even for small jobs.

Ready to get started? With the right tools and safety gear, you can use wire connectors with confidence. For more tips and quality products, check out the Huamao Electronics product page.

Getting a safe and strong connection starts with the right steps. You want your wiring job to last and pass any inspection. Let’s walk through each part of the process, from preparing your wires to using different types of wire connectors.

Before you connect anything, you need to get your wires ready. Clean, well-prepared wires help you make a solid connection.

Follow these steps:

Gather your tools and materials. You’ll need wire strippers, pliers, the right wire connectors, and insulation like electrical tape or heat shrink tubing.

Cut off any old, damaged, or twisted wire ends. Always start with a fresh end.

Use your wire strippers to remove about 1/2 to 3/4 inch of insulation from each wire. Check your connector’s instructions for the exact length.

Make sure you don’t nick or damage the wire. A semi-automatic wire stripper can help you get a clean strip every time.

Check the wire ends. They should be clean and free of frayed strands. If you see any damage, cut and strip again.

Tip: For screw terminal connectors, bend solid wires into a hook shape. For stranded wires, keep the ends neat and straight.

Twist-on connectors, also called wire nuts, are common in homes and offices. They come in different colors for different wire sizes.

Here’s how you use them:

Turn off the power and double-check with a voltage tester.

Strip the wire ends to the right length. Most twist-on connectors need about 7/16 to 1/2 inch of bare wire.

Connector Model | Recommended Wire Strip Length |

|---|---|

CWLD12 | 7/16 inch |

CWLD13 | 7/16 inch |

CWLD17 | 1/2 inch |

Hold the wires side by side. Use lineman’s pliers to pre-twist them together for a strong bond.

Place the wire nut over the twisted wires. Twist the connector clockwise until it feels tight.

Tug each wire gently to make sure nothing slips out.

Wrap the connection with electrical tape or use heat shrink tubing for extra safety.

Note: Don’t force too many wires into one connector. Always match the connector size to your wires. Use waterproof connectors for outdoor jobs.

Push-in connectors make wiring fast and easy. You just push the wire in, and it locks in place.

Steps to follow:

Strip only a small amount of insulation—just enough for the connector, usually about 1/2 inch.

Insert the wire straight into the hole until it clicks or locks.

Make sure the wire is fully seated and cannot pull out.

Use these connectors inside approved electrical boxes or fixtures.

Check that the connector housing covers all bare wire.

Common Issue | Problem Description | How to Prevent or Fix It |

|---|---|---|

Pins Not Making Proper Contact | Bent or dirty pins cause bad connections | Inspect and clean pins; replace if damaged |

Connector Not Locking | Locking part is worn or blocked | Check and clean; replace connector if needed |

Intermittent Connectivity | Loose pins or damaged cable | Inspect and replace cables or connectors |

Signal Loss or Poor Quality | Corrosion or rough handling | Clean and handle carefully; avoid harsh environments |

Tip: Always use push-in connectors that meet safety codes. If you feel any wire is loose, remove and reinsert it.

Lever connectors are quick and reliable. You can see the wire inside, so you know it’s connected right.

How to use lever connectors:

Strip the wire to the length shown on the connector (usually about 11 mm or 0.43 inch).

Lift the lever to open the slot.

Insert the stripped wire all the way in.

Push the lever down to lock the wire in place.

Repeat for each wire you need to connect.

To remove a wire, just lift the lever and pull the wire out.

Note: Lever connectors save time and let you check your work visually. They are reusable, so you can adjust your wiring if needed.

Screw terminal connectors are common in outlets, switches, and some terminal connector blocks. You need to tighten the screw to hold the wire.

Here’s what you do:

Strip about 3/4 inch of insulation from the wire.

For solid wire, bend the end into a hook. For stranded wire, keep the end straight or use a ferrule.

Place the wire under the screw or into the terminal slot.

Tighten the screw with a torque screwdriver. Follow the manufacturer’s torque specs for safety.

Wiggle the wire gently and retighten if needed.

Check for corrosion or loose screws. Use dielectric grease if you work in damp places.

Tip: Don’t overtighten the screw. Too much force can damage the wire or connector. Always use the right tool for the job.

You can find a wide range of wire connectors, terminal connectors, and wiring harnesses at Huamao Electronics. Their products meet strict quality standards and help you get safe, reliable results every time. For more details, visit the Huamao Electronics product page.

You should always think about safety when using wire connectors. Here are some tips to help you stay safe and finish your project without problems:

Turn off the power before you start working.

Pick the right size and type of wire connectors for your wires.

Check wires and connectors for cracks, damage, or metal showing before using them.

Do not plug too many things into one outlet. Use different outlets for your devices.

Change any cords, plugs, or connectors that look damaged right away.

Keep water away from all electrical work. In wet places, use ground fault circuit interrupters (GFCIs).

Wear safety gear like insulated gloves and safety glasses.

Check your wiring harness and terminal connector setups often.

⚡ Tip: If you see lights flicker, outlets feel warm, or you smell something strange, stop and check your connections. These signs can mean something is wrong.

A lot of beginners make the same mistakes with wire connectors. Try not to do these things so your connections stay safe and work well:

Using single-use connectors more than once. Some connectors are only for one-time use.

Stripping wires with a knife or boxcutter. This can hurt the wire. Always use a wire stripper.

Picking the wrong size connector. If it is too big or too small, it will not hold the wire right.

Twisting twist-on connectors too much. This can break the wires inside.

Taking off too much insulation. If wire sticks out of the connector, it is dangerous.

Mistake | Why It’s a Problem | How to Avoid |

|---|---|---|

Reusing connectors | Weak or unsafe connection | Use new connectors each time |

Wrong size connector | Poor fit, risk of failure | Match connector to wire |

Too much insulation off | Exposed wire, shock risk | Strip only what’s needed |

Sometimes you need an expert to keep things safe. Call a licensed electrician if you notice:

Lights flicker in more than one room

Outlets feel warm, look burned, or plugs do not fit tight

Circuit breakers trip a lot

You get a shock when touching switches or appliances

Wires look damaged, frayed, or melted

You smell something odd from outlets or devices

Trying to fix these problems yourself can cause shocks, fires, or damage to your wiring harness. Using the wrong terminal connector or broken wire connectors can also cause problems later. For hard jobs or if you feel unsure, always call a professional. You can find good, safe products and more tips at Huamao Electronics.

You now know how to use wire connectors safely and get reliable results. Here’s a quick checklist to keep in mind:

Prepare your wires carefully and pick the right connector for your wiring harness or terminal connector.

Follow each step, test your work, and use the correct tools.

Double-check every connection before turning the power back on.

If you feel unsure, ask a professional for help.

Remember, taking your time with wire connectors keeps your projects safe and trouble-free for years.

You should check your wire’s size and type. Look at the job you need to do. For example, use a twist-on connector for home wiring. For more help, visit the Huamao Electronics product page.

Most wire connectors are for one-time use. If you remove a connector, always use a new one. This keeps your wiring harness safe and strong.

Try a different size connector. Make sure the wire gauge matches the connector’s range. Using the wrong size can cause loose connections or safety risks.

Yes, you need wire strippers, a crimping tool, and sometimes a screwdriver. These tools help you make a secure connection. For cable assembly, having the right tools makes your job easier.

You can find high-quality wire connectors, terminal connectors, and electronic wire at Huamao Electronics. They offer many options for every project. Check their site for more details and support.

Need help choosing the right connector? Contact Huamao Electronics for expert advice and custom solutions!