close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-08 Origin: Site

What does a wiring harness do for a car? Wiring harnesses are the unseen heroes of your car’s electrical system. But what exactly do they do?These bundles of wires power everything from lights to safety features. Without them, your car would struggle to function properly.In this post, you’ll learn how wiring harnesses connect your vehicle’s electrical components and why they’re crucial for performance and safety.

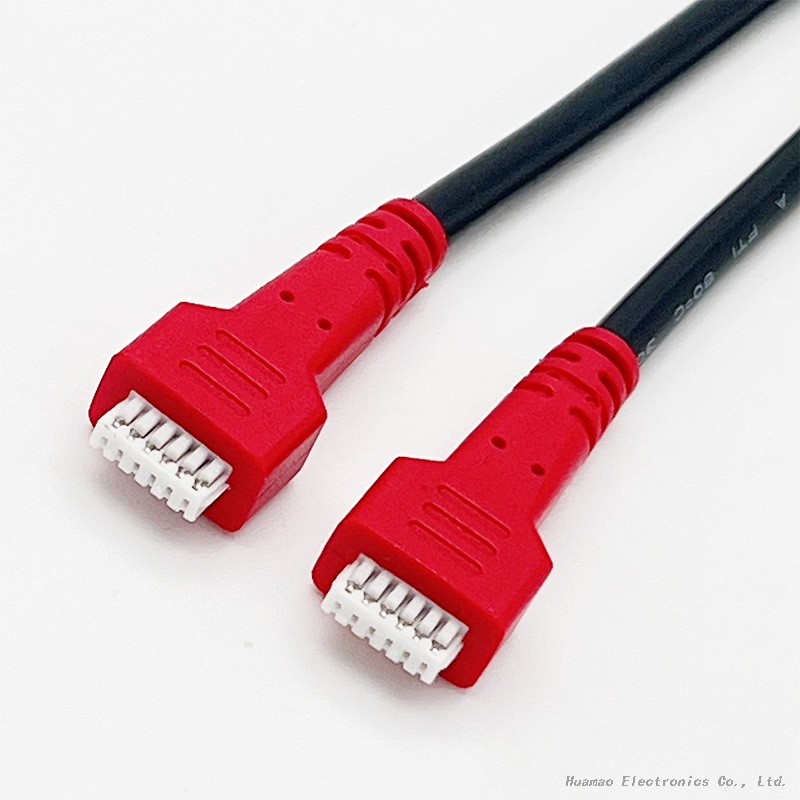

A car wiring harness is a collection of wires, connectors, and other components that transmit electrical power and signals throughout your vehicle. Think of it as the nervous system of your car. It connects essential parts like the engine, lights, sensors, and safety features, ensuring everything works smoothly.

Wires: The basic element that carries the power and data.

Connectors: These link wires to various electrical components.

Terminals: These are the metal connections that allow current to flow.

Clamps: Hold the wires in place, keeping everything organized and secure.

A car's wiring harness is like the nervous system in your body. Just as nerves transmit signals to control movement, the wiring harness sends electrical signals to control the car’s functions.

A wiring harness plays a crucial role in a car's electrical system. Here's how it works:

It links various components such as sensors, ECUs, batteries, and actuators. This connection allows the car's parts to communicate, ensuring they work in harmony.

The harness delivers electrical current to essential parts, like lights and the engine. It also sends data signals for safety features, climate control, and infotainment systems, keeping everything functional.

By bundling wires together, the harness keeps the system neat and compact. It helps save space and ensures the system is easier to manage. Additionally, it reduces the risk of electrical shorts and damage.

Wiring harnesses protect wires from damage caused by vibration, abrasion, moisture, and other environmental factors. This protection ensures the longevity and reliability of the car's electrical system.

Wiring harnesses come in various types, each serving a specific function in your car’s electrical system:

This is the core harness connecting most electrical components across the vehicle. It manages power distribution and signals for the entire system.

It links essential engine components, like the alternator and spark plugs. It also sends signals to control vehicle performance, ensuring everything runs smoothly.

The A/C harness connects climate control systems within the car. It ensures the air conditioning and heating components work efficiently.

This harness manages interior features such as lights, power windows, and door locks. It powers these components, making them functional for convenience.

Located beneath the car, the floor harness connects wiring for undercarriage and floor systems. It ensures these parts receive the necessary electrical power.

These harnesses serve unique functions, like the antenna harness for signal reception, the EPB harness integrated with wheel speed sensors, and those for sliding doors, ensuring smooth operation of these specialized components.

A wiring harness is vital for ensuring your car's electrical systems work efficiently and safely.

The harness ensures everything from lights to brakes works smoothly. By connecting all electrical components, it allows each part to receive the right power and signals.

Wiring harnesses are key to your car’s safety features. They support systems like airbags, braking mechanisms, and sensors, all of which are crucial for safe driving.

Modern cars depend heavily on wiring harnesses for advanced technology. Features like ADAS (Advanced Driver Assistance Systems) and infotainment systems rely on it for communication between various components, ensuring everything operates correctly.

Wiring harnesses can face several issues that affect the car's performance and safety.

Battery Terminal Corrosion: Corrosion on the battery terminals can disrupt the flow of electricity, leading to electrical failures.

Chafing and Wear and Tear: Over time, the wires can rub against surfaces or experience friction, causing damage or breaks in the wiring.

Thermal Expansion: Temperature changes can cause the wires to shrink or expand, leading to disconnections or electrical malfunctions.

A failing harness can cause serious problems like:

Engine Shutdown: Loss of power to the ignition circuit can shut down the engine.

Ignition Problems: Faulty wiring may prevent the car from starting.

Malfunctioning Lights: Lights may flicker or stop working due to poor connections.

When the wiring harness is damaged, power loss and short circuits can occur. These can result in component malfunctions, making the vehicle unreliable and unsafe to drive.

The lifespan of a wiring harness depends on various factors, but understanding these can help you know when it’s time for a replacement.

Environmental Conditions: Exposure to moisture, extreme temperatures, and dirt can damage the harness over time.

Driving Habits: Aggressive driving or frequent short trips can lead to wear and tear, shortening the harness’s lifespan.

Maintenance Practices: Regular maintenance can help identify issues early, prolonging the life of your wiring harness.

Under normal conditions, a wiring harness typically lasts 10 to 15 years. However, this can vary depending on the vehicle type and maintenance.

If you notice signs like:

Visible Damage: Cracked or exposed wires are a clear indicator that replacement is needed.

Malfunctioning Systems: Issues like engine shutdown, flickering lights, or electrical failures suggest the harness may be failing.

While it might be tempting to continue driving a car with a faulty wiring harness, doing so can be dangerous and lead to further damage.

A damaged wiring harness can cause:

Engine Failure: The harness powers vital components. If it fails, the engine could stop unexpectedly.

Loss of Power: The electrical system may fail, causing parts like lights and the starter to stop working.

Other Electrical Issues: Malfunctions in safety features like airbags or braking systems can occur, compromising safety.

Delaying replacement can lead to more serious problems:

Safety Concerns: Electrical failures in critical systems increase the risk of accidents.

Long-Term Vehicle Damage: Ignoring the issue can damage other components, resulting in costly repairs.

If your wiring harness is faulty, it's important to know when to fix it yourself and when to seek professional help.

Minor damage, such as a loose connector or small break in the wire, can often be repaired. However, if the damage is extensive or involves critical components, a full replacement is necessary to ensure the safety and reliability of your vehicle.

DIY Fixes: Simple issues like reconnecting loose wires or replacing a damaged connector can be fixed at home. However, you should have the right tools and knowledge.

Professional Help: If the damage is severe, like a burnt or deeply damaged wire bundle, it's best to consult a professional mechanic. They have the expertise to handle complex repairs.

Repair Costs: Minor repairs might cost between $100 and $500, depending on the issue.

Replacement Costs: Replacing a wiring harness can range from $1,000 to $1,500, or more, depending on your car's make and model.

Factors Affecting Price: The severity of the damage, labor costs, and the type of vehicle can all influence pricing.

Taking steps to maintain your car's wiring harness can save you from costly repairs down the road.

Periodic checks are crucial. Regularly inspecting the wiring system can help catch issues before they become serious problems. This includes looking for wear, corrosion, or signs of damage in connectors and wires.

Avoid Moisture: Water can corrode wires and connectors, so keep your wiring dry.

Reduce Wear: Ensure wires aren’t rubbing against sharp edges or moving parts. Proper insulation and protection can prevent this.

Proper Routing: Make sure the harness is routed correctly to avoid stress on the wires. This will keep them in good condition longer.

Always use quality parts. Investing in durable connectors and well-made wiring harnesses can help avoid premature failures and extend the lifespan of your vehicle’s electrical system.

The automotive industry has seen exciting developments in wiring harness technology, making them more efficient and reliable.

Advantages of Aluminum Alloy: Modern cars are using high-strength aluminum alloy wires instead of traditional copper. Aluminum offers a lightweight solution, reduces costs, and maintains strength, making it ideal for engine harnesses.

Optical Harnesses: These harnesses use light instead of electricity to transmit data. They offer faster speeds and better resistance to electromagnetic interference, improving data transmission for advanced systems like ADAS.

EPB Harnesses: The integration of wheel speed sensors into the EPB harness reduces weight and cost while maintaining performance. This innovation helps streamline the vehicle's electrical system.

Modern Design Tools: Tools like EDA (Electronic Design Automation) software enhance wiring harness functionality. They allow for better planning, ensure high-quality designs, and improve integration across the vehicle’s electrical systems.

The process of designing and manufacturing a wiring harness involves several critical steps to ensure it functions effectively in the vehicle.

Engineers design wiring harnesses by considering the vehicle's electrical load, required connections, and component placement. They map out the system’s needs and ensure all parts are properly linked to avoid electrical faults.

The process begins with creating detailed 2D designs, showing how wires are routed and connected. These are then translated into 3D models for further refinement. Once the design is finalized, manufacturing begins by cutting wires, assembling components, and testing the system’s functionality.

Data Inconsistency: Inconsistent data across design teams can lead to errors and delays.

System Integration: Ensuring all components work seamlessly together can be challenging.

Validation Issues: Physical prototyping is necessary to test designs, but issues may arise late in the process.

Benefits of Using EDA Tools: These tools ensure data consistency, improve design validation, and help reduce time-to-market by streamlining the design process.

How Simulation Helps Ensure High-Quality Harnesses: Circuit simulations allow designers to detect issues early, preventing costly errors and improving the overall quality of the harness.

Wiring harnesses are vital for a car's electrical system, ensuring smooth operation and safety. Regular maintenance and timely replacement are essential for optimal vehicle performance. If you notice issues, inspect your vehicle's wiring harness and consult a professional to avoid costly repairs and safety risks.

A: Common causes include battery terminal corrosion, wear and tear, thermal expansion, and chafing.

A: Driving with a faulty wiring harness is risky as it can lead to engine failure, electrical malfunctions, and safety system failures.

A: Look for visible damage, malfunctioning electrical components, or issues like engine shutdown and ignition problems.

A: Wiring harnesses typically last 10-15 years, depending on environmental factors and maintenance.

A: Minor damage can be repaired, but extensive damage often requires full replacement for safety and reliability.